Global Clean Coal Technologies™ (Aust) Pty Ltd

Developing and supplying leading-edge visual and thermal imaging technology solutions.

- Significant cost and operational savings;

- Environmental benefits; and

- Improved operator safety.

GCCT™ team has extensive experience and qualifications in business development, marketing and commercialisation, infrared thermography, performance modeling of combustion image processing algorithms for clean coal technology using parallel computing platforms.

Our Technology

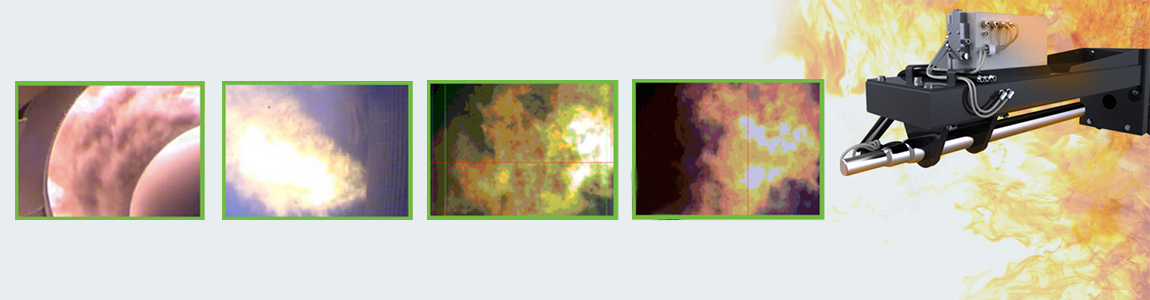

The GCCT® technology is a non-touch monitoring technology system for combustion optimization and clinker monitoring.

The technology measures the primary information (directly from the combustion dynamics) providing a visual tool for experienced combustion engineers to monitor the boiler burner and igniter flames and make additional changes necessary to improve the thermal efficiency of the coal-fired generators and significantly reduce the greenhouse gas emissions.

The technology provides real time images of the burn, the slag and the state of the boiler. These images and data captured can also be used to monitor and reduce the amount of slagging, thereby reducing the maintenance costs.

Specifications

The GCCT™ furnace camera system incorporates an automated electronically controlled pneumatic retraction and extension control system to protect the camera against high temperature in the event of an air, water or electrical supply failure.

- Temperature monitored furnace camera with carriage for fixed installation.

- Can be operated locally or remotely via the plant control system.

- All cameras can be connected to the network via video web servers and monitoring remotely.

For installations where cooling water is not available or can not be used, there is a camera mounted cooling system as an option. The cameras are manufactured with customised docking collars and length of the camera lance designed for the specific installation.

Learn more about the GENZ™ cameras here.